Aceti Macchine designs and manufactures machinery for metal processing and finishing.

Experience and knowledge developed over decades with the sale of thousands of machines positions the company as a leader in its sector both in Europe and around the world.

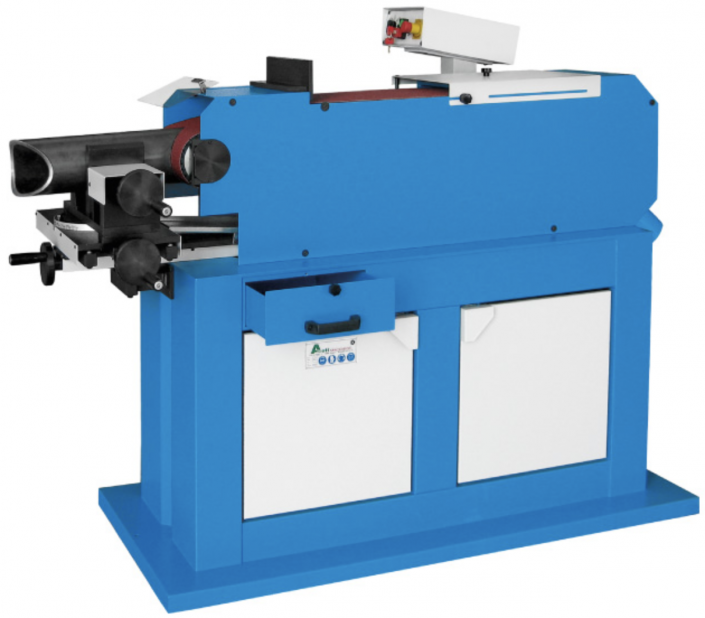

Since 1979 over 100 models have been produced, including belt grinding machines for satin finishing, pipe notcher, deburring machines for metal sheets and tubes, beveling machines, belt and disc grinding machines, polishing and buffing machines, grinding machines, drill sharpening machines, end mill sharpening machines, tool sharpening machines and dust extractors.

Our products are used in numerous different industries: mechanical engineering, carpentry, steelworks, shipbuilding, railways, manufacture, vehicles, furniture, metal polishing and many more.

We have always been devoting ourselves to the realization of machines and systems universally recognized as a synonymous of reliability and technical lead. Our work consists in projecting and realizing the best technology for solution of a large range of problem of grinding, buffing, polishing, cutting, bevelling and generally of automation difficults.

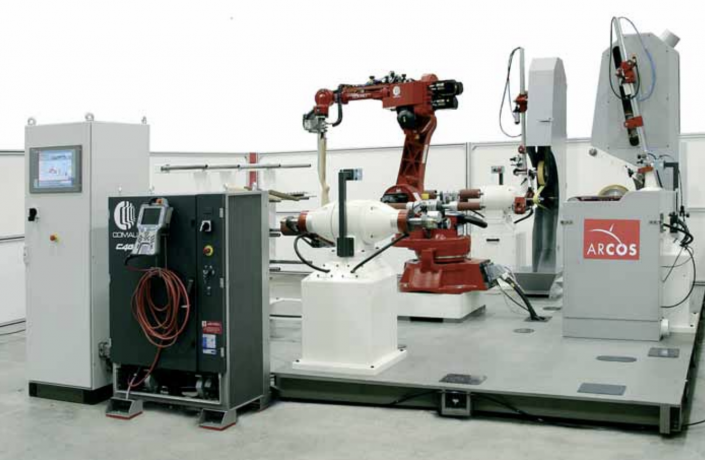

To understand better secrets of our success we think we are obliged to explain how we develop our projecting and producing work in ARCOS. First of all, we always start with a careful analisys of problematics put to us and our Customers’ observations.

Is our strong determination to combine our personal professional experiences with our Customer ones, so we can quickly put our efforts in a winning technical solution. This first step generates the propose of an adequate plant for the object attaintement.

CAD projecting

CAD projecting, strenghtened by tests effected in Company, determinates the certainty of attaintement designs. Following confrontation with Customer and its approval permit system production.

Naturally, in ARCOS opinion, to produce means to create only and exclusively high quality machines. This implies that we must scrupulously follow an ancient formula formed by capacity, professionalism, a rigouros industrial process and a modern technolgy strenghtened by the best international components industry. An excellent productive process generate firm, effective and dependable.

Assistance and reparation polishing and grinding machines

Clearly our roll does not finish with the starting of our systems. Our expert practitioner team permanently guarantees a fast and careful assistance service where our machines are placed Our essential object is, and always it will be, our Customers’ complete satisfaction.

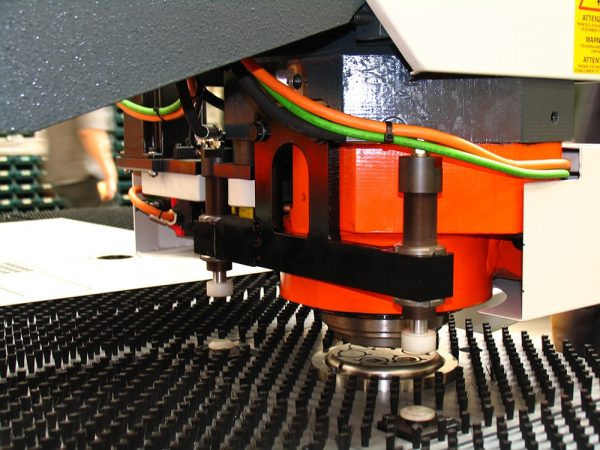

IMAC Italia, property of Lodesani & Carreri Srl, is an historical Italian leader company in the field of production of machines for sheet metal industry that you can find on the global market.

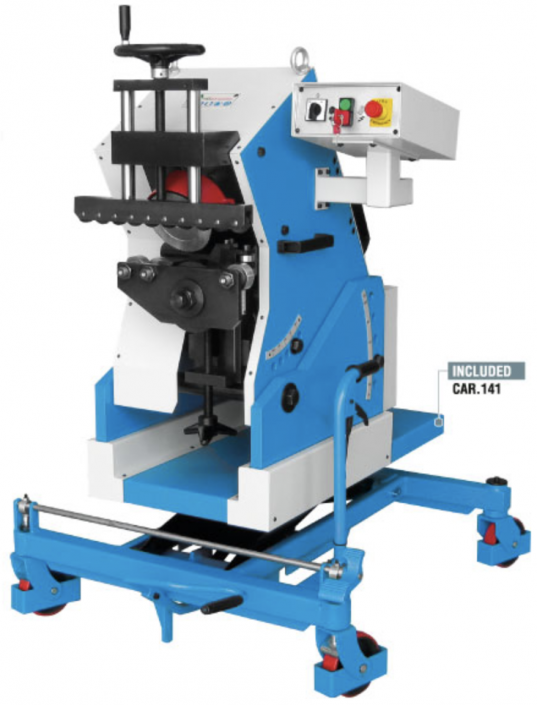

Founded in 1973, IMAC Italia designs, develops, produces and sells traditional and CNC fabricating machine tools like Notchers, Bevellers, Punching machines, Shears and Press Brakes. The long-time experience of its own technicians and the continuous studies and internal development, allow to the Staff IMAC a constant improvement and innovation of quality of its own products.

IMAC Italia produces technological state-of-the-art machines but at the same time very easy to use.

The IMAC Italia’s machines are designed in order to respect the requests and personalized need of each customer with the goal of supporting and associate with him during all its competitive challenges in the market.

Mille miglia

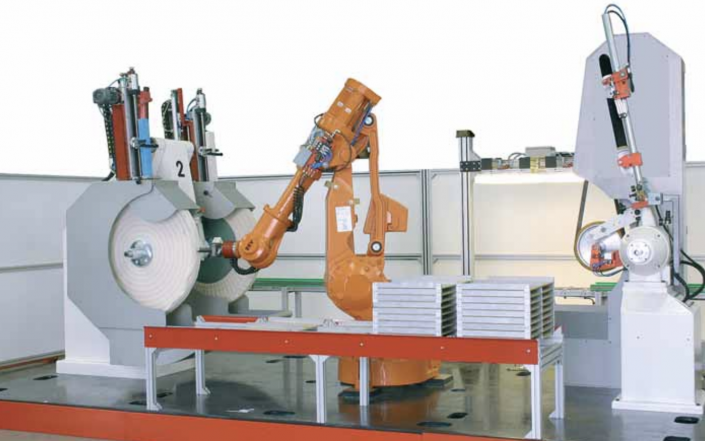

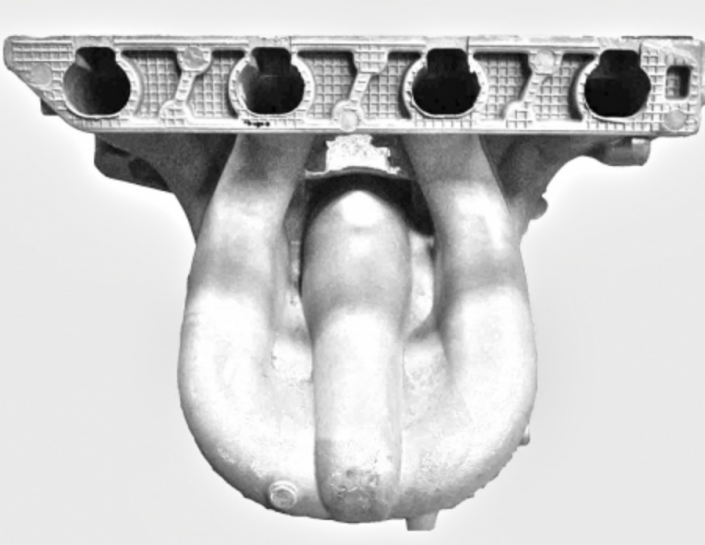

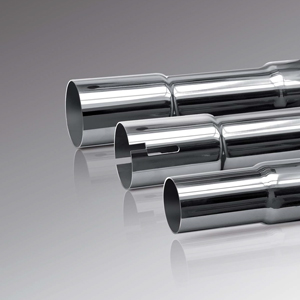

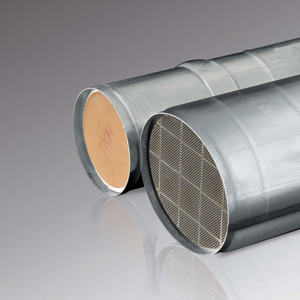

Mille Miglia Engineering s.r.l. has been working for over 30 years in the field of research, design, manufacturing and supply of tooling, checking fixtures and machines for various applications in complete exhaust systems of cars and industrial vehicles, according to state-of-the-art technology and with the utmost respect of the safety laws and recommendations.

• One, two or more working heads, hydraulic or electro-pneumatic

• Machines for tube expanding by means of segment inner fingers and conical punch

• Machines for tube reducing by means of segment outer jaws and conical ring

• Machines for tube notching on the extremities of straight or pre-bent tubes; simple notches or torca-slots and reference slots.

• Tubes or metal sheet cutting units

• Machines for tube expanding and/or reducing, C-type endsizing

• Patented torca-slot device on C-type endsizers

• Machines for tube expanding and/or reducing, I/O-type endsizing, inner/outer endforming

• Machines for ram forming by means of vice jaws and ram tool (punch)

• Machines for cutting and trimming of straight or pre-bent tubes

• Sawing machines

• Machines for tube perforation

• Machines for pressfitting of inner pipes into baffles or complete muffler assembly

• Machines for mechanical ridge-locking through expansion of the muffler inner pipes

• Machines for simultaneous pressfitting and ridge-locking

• Working cells for catalysers and canning production

• Machines for substrate measurement, mat/substrate pressfitting into the shell, canning reducing/expanding

• Machines for final endsizing of complete canning

• Machines for substrate/mat pressfitting into the shell

• Machines for sizing and perforating of shells or complete canning

• Machines for expanding of tubes with flanges

• Machines for piercing and/or squeezing on tubes

• Machines for marking and engraving of logos or numbers on tubes

• Machines for tube deburring with brushes or inner/outer cutters

• Machines for chimney pipes applications

• Machines for leak testing and good/reject parts results issuing

• Machines for exhaust systems assembly and sheet cutting lines

• Multi-operation machines

• Customized machines and working cells, turnkey solutions, no limit with tube diameters

F.lli Vimercati s.n.c. was founded in 1973 as a business venture in Brianza, north of Milan, on the initiative of the four Vimercati brothers and partners, Marco, Mario, Sergio and Antonio, who are still currently guiding the company. It is specialized in the production of Press Brakes and Shears.

All production is entirely manufactured inside their productive plant in Sovico (MB). The company covers an area of 7,500 m2 organised in various departments equipped with the most advanced technological machinery: carpentry, boring, grinding, lapping, CNC milling and lathes centres, sanding and painting plants, assembly of electrical plants, and automatic storage systems.

Qualified staff deal with the production process and take care of it in detail and manage the after sales service.

The company philosophy is based on the study of customized solutions that are tailored to customer requirements. Attentive to the evolution of the market and development of new technologies.