Since 1972, CHIA-MO has been designing and manufacturing precision accessories for machine tools. Our experience acquired long-term and use of next generation technologies have enabled us to develop an ever broader, better quality production plan to satisfy the needs of our many costumers.

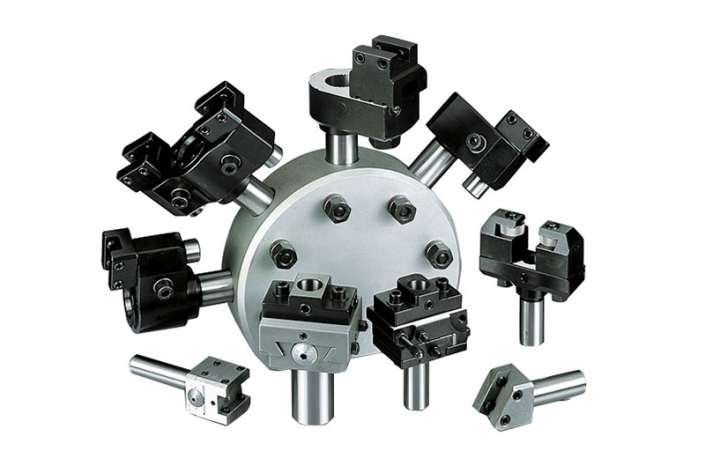

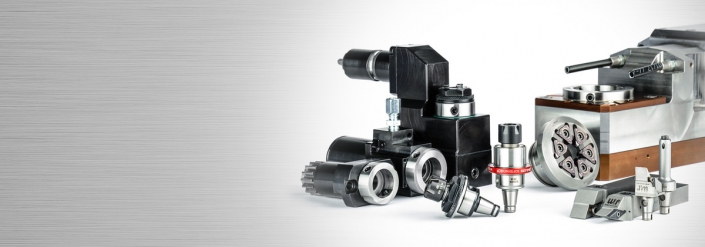

Chia-mo produces machine tool equipments, lathe collets DIN 6343, clamping systems, barloader collets, barloader revolving, hard metal bushes, sealed collets, cnc lathe tool holders, boring bar sleeves, collet spindles DIN 6499, broach tool holders, broaches, live centres, VDI 3425-2 toolholders DIN 69880, reamer holders, tap holders, die holders, knurl holders, bar stops, pneumatic chucking devices, spare parts, collet holder sleeves, clamping levers, gears and special chunk on design.

The company performs all design, work and final-test stages in-house, thus ensuring high quality and high precision products.

The high quality of the final product is an essential part of our corporate philosophy.

The entire production process is accurately controlled, starting off from certified and tested materials and heat treatments, and using “SIT” certified measuring instruments for the final quality control.

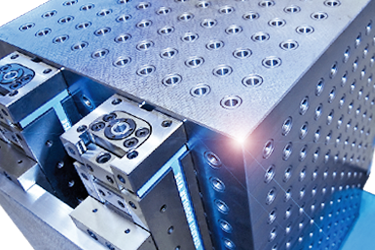

Each step of the production process is carried out with innovative machinery, it is checked and tested and is recorded via a barcode.

Before shipment all the material is subjected to a rigorous final testing.

1971

Gerardi S.p.A. Co. established by Ivano Gerardi Sr. in 1971 with a background of 20 years experience in all kinds of machine shop throughout Canada and U.S.A. Today the company is just 5 Km from the Milan International Airport Malpensa 2000.

1980

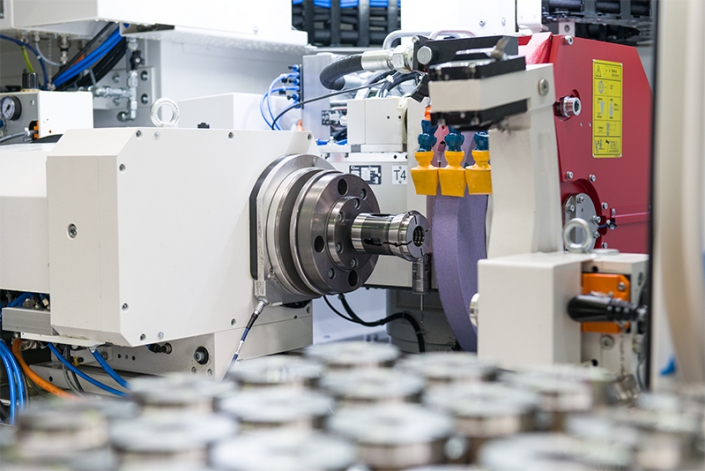

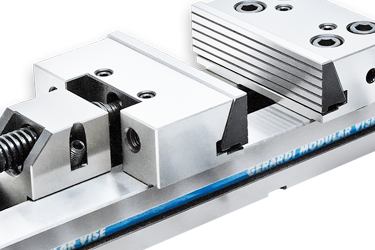

In the eighties the company grew to become the largest Italian vise manufacturer, one of the leaders in the European Common Market and the quality of its products gained worldwide renown and solutions Meanwhile, the company developed its own Grinding machines with a totally new concept at the base of the project. Moreover Gerardi S.p.A. has designed a widest range of Angle Heads for traditional machine tools and machining centers and Driven Tools for C.N.C. lathes. With worldwide marketing efforts, the company brought the production from few pieces to and such thousands technologies to be known and sold all over the world.

1990

The new machine was exhibited at the Milano machine tool show in 1990 and since then the research and development of the grinding technologies have never stopped. In the same period the company established a joint-venture in China for the manufacturing of parts and types of vises together with the Chinese aerospace industry. Thanks to major investments the new company is today fully controlled by Gerardi and is achieving the same excellent leadership results in Asia as those accomplished in Europe.

2000

After the set up of a US subsidiary Co. near Chicago (Huntley – IL), new German and English branches, have been estabilished in Stuttgard / Germany in 2007 and in Bristol / UK in 2010 in order to better penetrate and service the local markets. Of course this meant a huge financial effort and investment, but the fast evolution and continuous adjustment to high competitive markets has always been the main Gerardi S.p.A. feature.

2012

Gerardi sets up a new plant for angle heads manufacturing in LONATE POZZOLO and a new company in INDIA for the manufacturing of fixtures for the Indian market.

2015

The Gerardi S.p.A. Co. staff nownumbered over 200 employees, with an averageage of under 40. In the company all the top roles and manager positions were acquired through internal training and experience geared to devoloping individual skills and abilities. Our total export is today more 70% of our total production in more than 50 countries around the world and we invest about 10% of our total turnover in advanced technological research for new products.

The name ROMAI, perhaps more than any other, is synonymous with precision.

At the foot of picturesque vineyards transmission gears are made, which are highly-esteemed throughout the whole world. For medical technology, automotive, wind energy, aerospace industry, household appliances, solar energy, tool and machine building.

For more than 50 years, ambitious construction and real net output ratio (> 80 %) belong to the quality guarantees of ROMAI. The company is still family property. More than 80 employees work meticulously every day to offer the high quality requirements at an excellent value at an appropriate time.

1991:

Founding of W&F Werkzeugtechnik GmbH in Gingen.

1993:

Enlargement of warehouse and office space. Move to Reichenbach a. d. Fils

1995:

Expansion of the clamping program. In addition to the standard program, W&F also offers tool holders in up to five different lengths.

2001:

Relocation and foundation of the new company center in Großbettlingen.

2003:

Development of the modular precision interface WFU for the milling area.

2004:

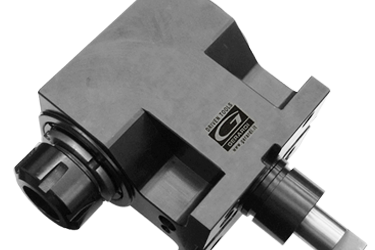

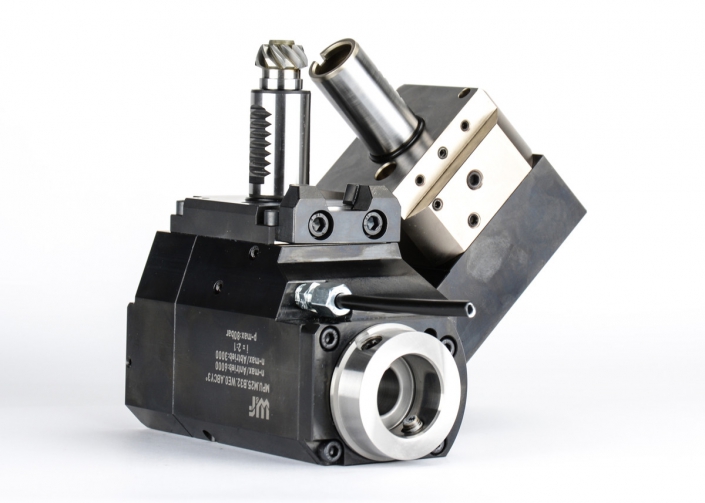

Development of the first high-accuracy quick-change system for driven tools WFB. This quick-change system is the first to combine precision, flexibility and functionality thanks to a cone-planing system with an additional cylindrical support collar.

2006:

Introduction to the art of turning. Development of the comprehensive tool program for all common machine manufacturers of short part turning machines.

2008:

Expansion of the product program by entering the long part turning technology. Start cooperation with well-known manufacturers of lathes and develop innovative system solutions for their machines.

2009:

Expansion of the company center in Großbettlingen by approx. 2,000 m².

2013:

Development of modular thread whirling machines with our patented quick-change system WFG. With a circular accuracy of <3μ and a repeatability accuracy of <2μ, this interface is not only characterized by its flexibility but also by its accuracy.

2014:

Development of modular turning tool holder – WF-Micro. With the development of the WF micro interface, we have succeeded in developing a modular quick-change system, which sets new standards in terms of precision and, above all, process safety.